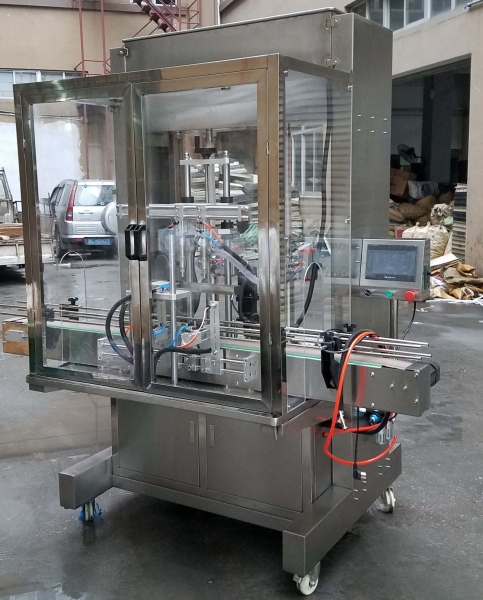

FULLY AUTOMATIC SERVO MOTOR LIQUID AND PASTE FILLING MACHINE

Quantity

This machine is the new-generation improved volumetric filling machine, controlled by microcomputer PLC programmable, equip with servo motor, photo electricity, transduction and pneumatic action. Widely used in daily cosmetic, pharmaceutical, oil and other industries, may fill different liquid products

Use servo motor control volume measurement is more accurate, the piston can always reaches constant position. Besides, it is easy to set filling volume and filling speed on Touch Screen.

No bottle no filling. It is equipped with counting function. Adopts anti-drip and anti-drawing’s filling head, lifting system to avoid foaming, bottle positioning system and liquid level control system.

Recommended products:

Disinfectant, washing detergents, washing liquid, dishwasher rinse aid, fabric conditioner, glass cleaner, bathroom sprays, kitchen sprays, bath cleaner, floor cleaner, floor polish, Edible oil etc.

Specification:

Power supply: single phase 220V 50HZ

Power consumption: 1.5 kw

Nozzle: 4

Filling size: 100-1000ml

Application: liquid or paste

Filling speed: 20-30 bottles / min

Filling precision: < ± 1%

Power: 220/110V 50/60Hz

Pressure: 0.5-0 .7 MPa

Air compressor required

Use servo motor control volume measurement is more accurate, the piston can always reaches constant position. Besides, it is easy to set filling volume and filling speed on Touch Screen.

No bottle no filling. It is equipped with counting function. Adopts anti-drip and anti-drawing’s filling head, lifting system to avoid foaming, bottle positioning system and liquid level control system.

Recommended products:

Disinfectant, washing detergents, washing liquid, dishwasher rinse aid, fabric conditioner, glass cleaner, bathroom sprays, kitchen sprays, bath cleaner, floor cleaner, floor polish, Edible oil etc.

Specification:

Power supply: single phase 220V 50HZ

Power consumption: 1.5 kw

Nozzle: 4

Filling size: 100-1000ml

Application: liquid or paste

Filling speed: 20-30 bottles / min

Filling precision: < ± 1%

Power: 220/110V 50/60Hz

Pressure: 0.5-0 .7 MPa

Air compressor required